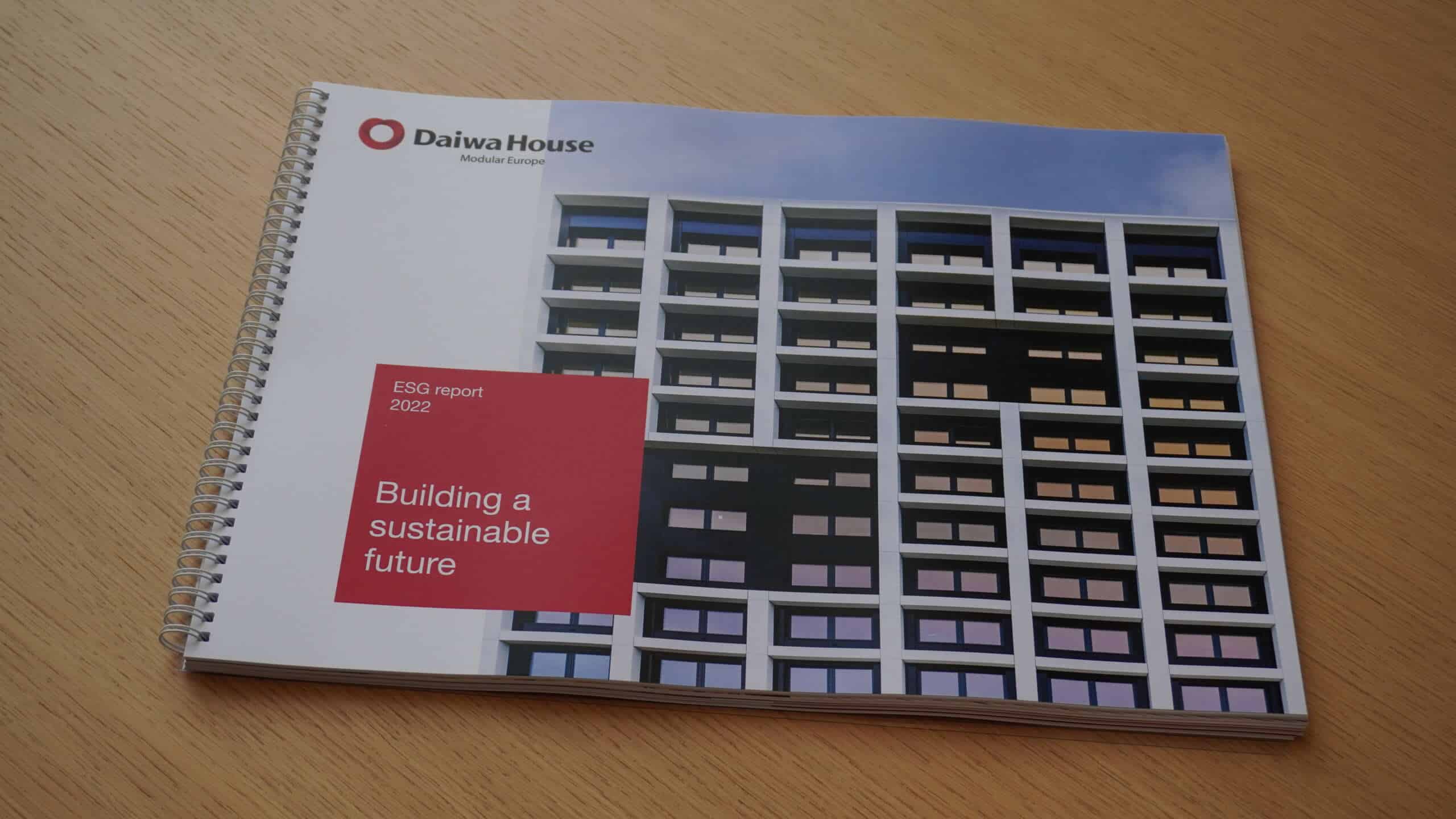

Modular industrial building

A comfortable, healthy and future-proof living environment makes dreams come true. A future-proof living environment is a sustainable living environment. The foundation of such an environment is formed during the actual construction process. For that reason, Daiwa House Modular Europe has opted for industrialised modular building.

This is a sustainable building method with minimal impact on the environment or society. It revolves around high quality, circularity and scalability, as well as comfort and affordability for future residents.

Complete housing solutions realised in our own production facilities

We manufacture major components of our housing solutions under controlled conditions in our own production facilities. At the project site, we then assemble these components to create our housing solutions. This building method goes beyond prefab construction, which only involves the advance production of individual elements.

With industrialised modular construction, entire residential modules combine to form a single building. For example, sanitary facilities are already pre-installed in our apartments before they leave our production facilities. On location, these are then combined to create an apartment complex.

Circular and detachable

Industrialised modular building revolves around circular and detachable building. This approach offers myriad benefits for people and our society. Just like traditional buildings, our modular housing solutions will last for decades. Instead of being demolished at the end of their life cycle, they will be reused for other purposes – often at a different location and with a different structure or design. Daiwa House Modular Europe’s housing solutions are circular and ready for the future, whatever it may hold.

Standardisation, fits well within any streetscape

But there is more. This method allows for the standardisation of the building process. Our housing solutions and the range of available options are fully designed already. Nevertheless, every new project that Daiwa House Modular Europe takes on is unique. Another major advantage of industrialised modular building is the customisability of the outer shell of the residences. We developed a range of styles that form the basis for the exterior of our housing solutions.

This serves as a great example of the tailor-made solutions we at Daiwa House Modular Europe strive to offer. As a result, we can realise our projects faster and with greater quality. Likewise, scaling up is not an issue. The realisation time of our housing solutions is thirty to fifty percent shorter than that of conventional construction methods – regardless of whether a project consists of just a few or several hundred residences.

Greater speed and quality

There are several reasons for the higher speed of realisation. The standardisation allows us to start our work on the project immediately once the building plans have been approved. The on-site activities can be conducted alongside the production of the residential modules.

Automation and robotisation support this process by facilitating higher labour productivity and a greater production speed. That increased productivity allows us to expedite the process at any scale, all while manufacturing every single element with the utmost precision. We can consistently guarantee the highest quality and offer our clients a realistic and feasible schedule. Last but not least, future residents can begin to enjoy their new home that much sooner.